News & Events

Kerr Dental Case Study

Situation:

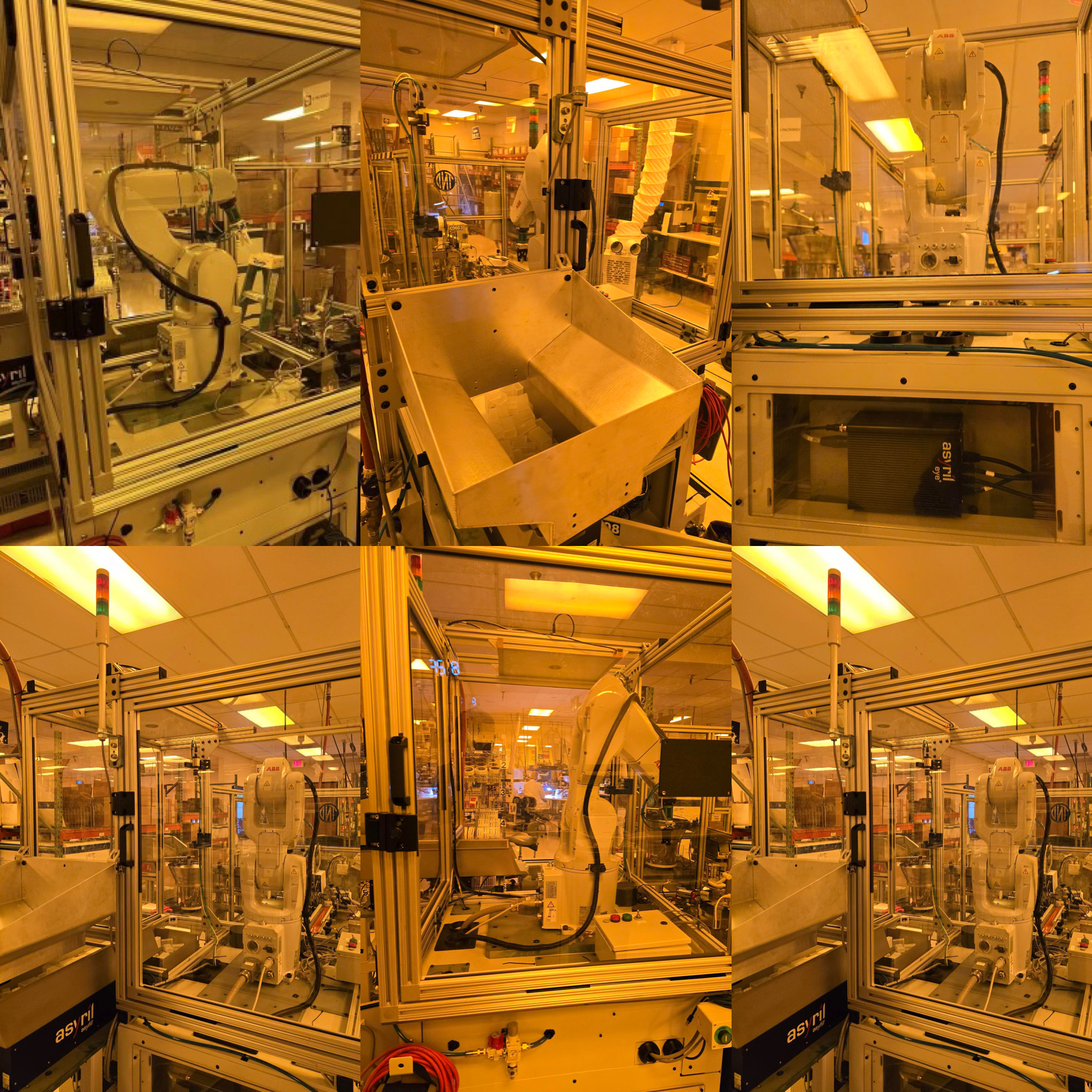

Challenged with increasing downtime and process inefficiency, Kerr Dental sought to improve their production by reducing operator involvement in their current process. Recognizing the need for greater automation, they decided that a robotic solution would provide the necessary flexibility and ease of adaptation to different production demands.

The solution required to pick and place products, ensuring that cycle times were met, and consistency was kept.

Mission:

The project team was tasked with developing a fully automated system that would minimize operator intervention and fit seamlessly into the existing production environment. The solution needed to pick the input product and place it on a current process line. Once the final product was ready the solution needed to check the quality of the finished product and place it on the output conveyor.

Execution:

With the help of our partners at Eagle Vision + Automation, we focused on creating a solution that was both flexible and reliable, overcoming challenges through innovative integration of advanced technologies. The goal was to ensure the system could adapt to varying production requirements while maintaining consistent efficiency.

Result:

The project successfully automated the process, reducing manual input and enhancing overall efficiency. Kerr Dental was pleased with the outcome, as it set a new benchmark for future automation initiatives.